![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin-ecovolta/_processed_/c/f/csm_ecovolta-evotractionbattery-piaggoape-5_e7d4ad984d.webp)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin-ecovolta/_processed_/c/f/csm_ecovolta-evotractionbattery-piaggoape-5_e7d4ad984d.webp)

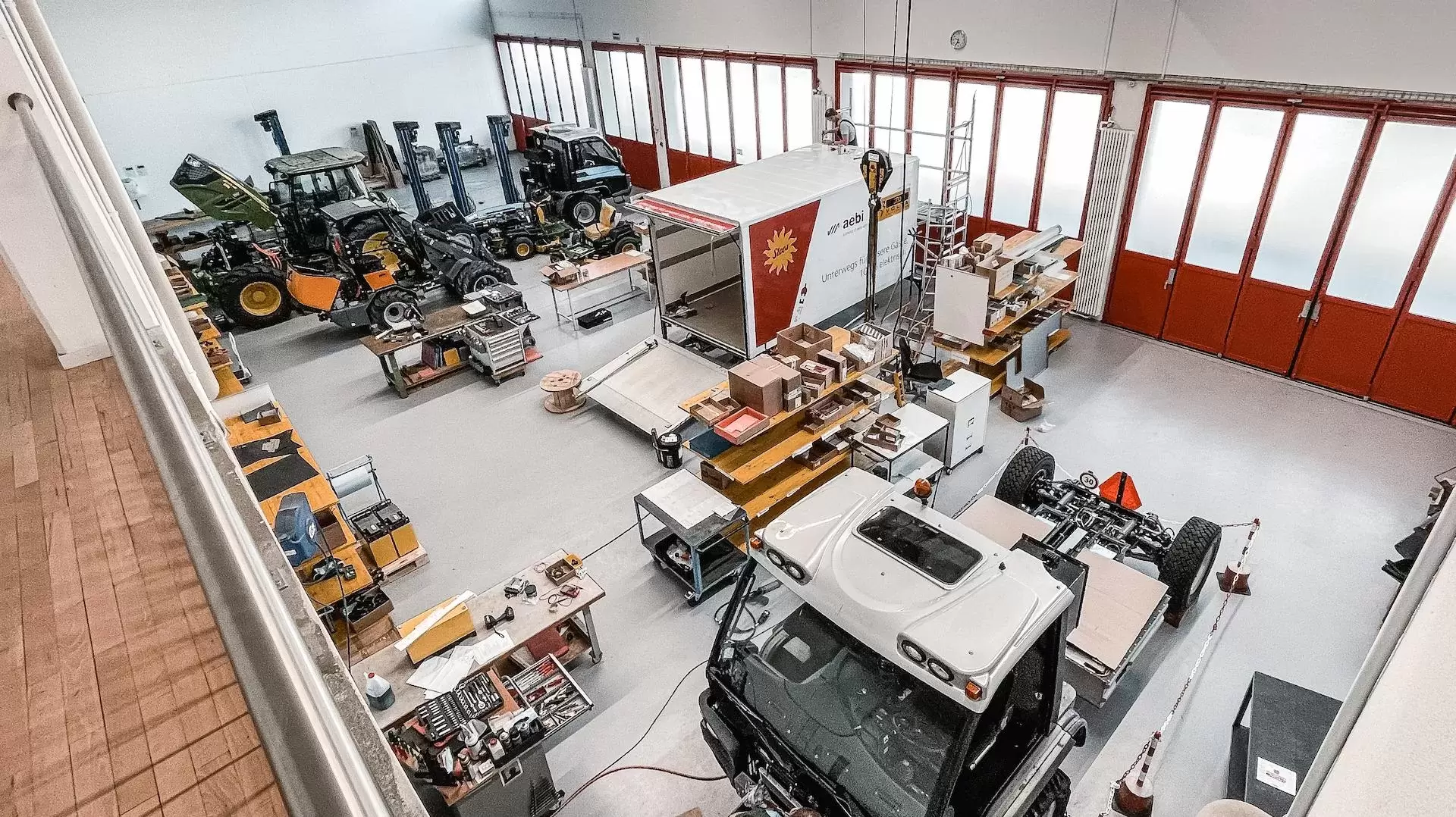

Design & Vehicle Modification

As a general rule:

The evaluation is strongly dependent on whether the vehicle is road-legal or not. With regard to the total weight, it is important to examine possibilities for adding weight at an early stage. In terms of installation space and capacities, you have several options thanks to ecovolta technology. Depending on the project and voltage range, you can connect up to 8 battery packs in series and 15 in parallel and distribute them optimally in the vehicle. As far as safety is concerned, conversions in most voltage ranges must be carried out and/or accompanied by qualified personnel. Functional safety, electrical safety, suitable motor performance and personal safety are elementary for the success of the project and market approval.

Battery applications are one of the core technologies of the eco Group. ecovolta customers experience these many years of experience from development and vehicle integration as well as from the partner network as a clear added value compared to pure battery trading.

ecovolta battery packs allow serial as well as parallel operation. The products thus ensure scalability and coverage of several voltage ranges. Where standard solutions are lacking, engineering covers your needs thanks to individual solutions.

The standardised battery production in Brunnen is complemented by our own research and innovation centre. The modern facilities incl. machinery allow the efficient construction of functional samples and small series.

Compared to thermally powered vehicles, electric vehicles are straightforward: The traction batteries are simply charged using the greenest possible electricity. When the "ignition key" is pressed, the main contactor closes, current flows from the battery to the controller, and the control unit sends signals and specifies how much electricity is transferred to the engine. A vehicle-specific adapter ensures that the engine and transmission are connected, and the vehicle drives - free of noise and pollutant emissions, with comparatively far fewer components and consequently lean maintenance.

Goal: Sample

Goal: Functional model (FuMo)

Goal: Prototype

Goal: pilot and/or small series

In allen Projektphasen unterstützt ecovolta und bietet das Gesamtpaket von Konzept bis zur Serienübergabe, inkl. Prototypenbau und Homologation.

Ja, bei einer Kleinserie von bis zu 10 Stück kann ecovolta Teile der Serienumbauten übernehmen.

Ja, ecovolta ist spezialisiert auf den Prototypen- und Kleinserienbau.

Ja, ecovolta arbeitet eng mit lokalen Prüfinstituten zusammen.

Ja, ecovolta bietet sämtliche Dienstleistungen bis und mit Fahrzeugzulassung an.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin-ecovolta/_processed_/c/f/csm_ecovolta-evotractionbattery-piaggoape-5_e7d4ad984d.webp)